An Unbiased View of machined parts

Manufacturing these custom made parts in a way that may be both equally swift and price-helpful can demonstrate complicated with no appropriate technological know-how or experience.

Hi HLH, I received the CNC prototypes previous 7 days and have used the previous few times assembling them. I wish to thank you and HLH for that operate you have finished CNC machining these parts and for offering them to us as rapidly as you possibly can. I stay up for dealing with HLH once again as new tasks crop up in the future.

That’s not to say the events didn’t work with the most effective of intentions, at the very least initially, but significant businesses like Time are ocean liners: They don’t activate a dime. In cases like this, it didn’t convert in any way.

The 5-Second Trick For cauldron

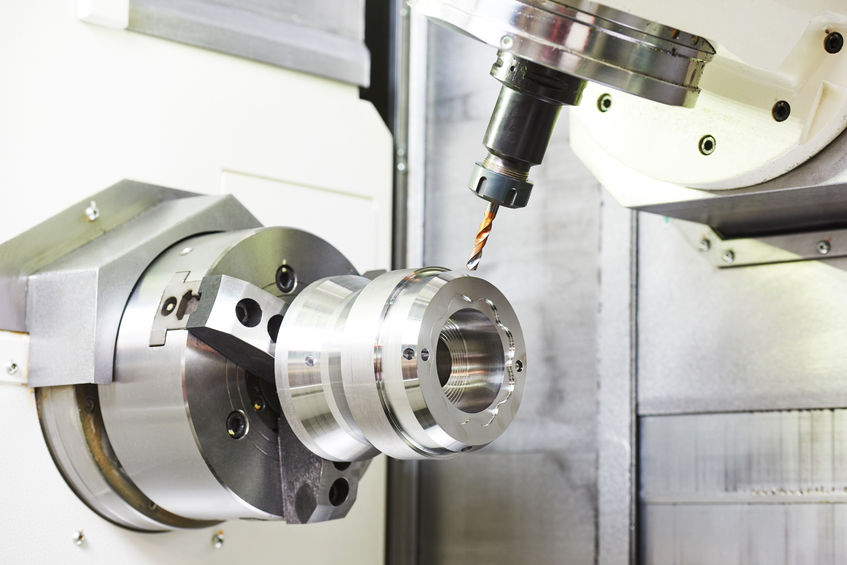

A cutting Device has a number of sharp reducing edges and is fabricated from a cloth that is tougher than the get the job done content. The cutting edge serves to separate chip from your dad or mum get the job done content. Connected to the cutting edge are the two surfaces on the Software:

No one owed me nearly anything; not Medium; not SI; absolutely not Simmons; no-one. I merely required to regroup and turn what felt just like a missed prospect into some thing positive.

high quality method production backorder procedure fixed Expense marginal Price

A good apply on thick cuts is to carry out a rough Reduce to remove the bulk of the material, then just take finishing Lower to eliminate the final .025 to .050 of an inch.

Justification me for my minimal vocabulary but is there an milling (little bit?) Which i can use for making finishing passes, to eliminate Individuals Resource marks?

How Much You Need To Expect You'll Pay For A Good cauldron

7. Style and design to avoid close mill chatter. End mills function very best when they are rigid, and the deeper a pocket is, the more probable the end mill will chatter. This ends in a very poor surface complete.Â

I conform to get these communications from SourceForge.net through the indicates indicated above. I know that I can withdraw my consent at at any time. caldeiraria Be sure to check with our Conditions of Use and Privacy Plan or Call Us For additional details.

Examining your design towards the decided on producing system to discover if any variations are required is good engineering practice.

Warning ! Abnormal warmth can be created by improper machining methods. If smoke is produced by machining, the method need to be immediately corrected. Will not inhale the smoke or grinding dust from urethane or any elastomer.

Top machined parts Secrets

a. A tool utilized to create a stage influence, Specifically a mechanical usually means of lowering an actor onto the phase.